Thermaltake Water 3.0 Extreme S AIO CPU Cooler Review

Peter Donnell / 9 years ago

Introduction

Thermaltake have created some fantastic coolers in recent years, with a range that covers everything from air, to water, budget to premium, including their new and rather stunning custom loop water cooling gear. The model we’re looking at today covers several categories, it’s an AIO water cooler, which promises the high-end cooling thrills of their other water coolers, with a more affordable price tag, making it very attractive to those investing in their first water-cooled setup.

Check out the quick overview video below to find out why Thermaltake stripped down some of the features on this cooler and why that’s a good thing for (most) consumers.

The packaging is colourful and has all the major specification information on there that you will need.

The interior is pretty much what we see with all AIO coolers, a carton with protective bags overall smaller hardware components to keep them safe.

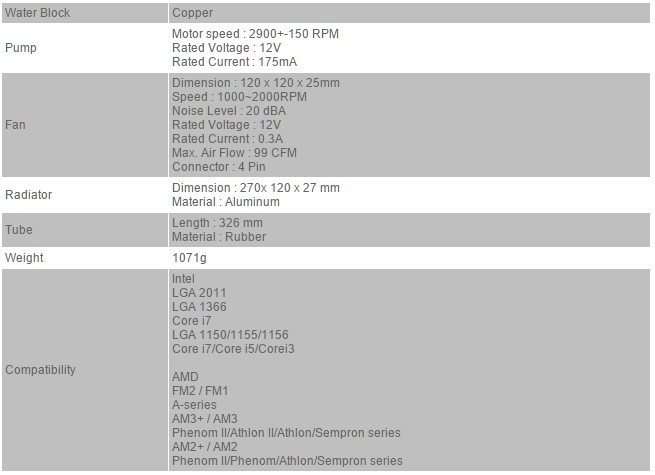

A pair of double curved fans, which can operate between 1200 and 2000 RPM, each fitted with a standard PWM connector and a black braided cable.

There’s no shortage of mounting options on offer, with separate rings and backplates for both Intel and AMD, 2011 screws, fan and chassis screws and even a Y-split PWM cable for the fans.

The radiator and pump are nicely designed, but also pretty standard. Those looking for something unique may want to look elsewhere, but it’s certainly presentable.

The radiator is a slim design, maximizing compatibility with most systems, while the 240mm length provides a good amount of surface area to dissipate heat from your CPU.

Two slim and long hoses mean that it’ll be easy to fit the pump inside your system, whether you have a small chassis, or a large one. The back of the pump has a Thermaltake logo on it, which looks pretty cool.

Pre-applied thermal paste is great for a quick and easy install, but there is no extra paste included, so you’ll need more if you plan to re-install in the future.

We won’t be using the stock paste of course, so I’ve cleaned it off. As you can see, we’ve got a good size copper contact plate and lots of screws providing a snug fit for the pump housing.