eTeknix Take a Tour of the Kingston Technologies Factory in Taiwan

Peter Donnell / 11 years ago

Last week while we were attending Computex 2014, the eTeknix team, or more importantly myself, and the eTeknix boss Andy, stopped by the Kingston head office for a quick tour of their factory. This factory is their central hub where they create their memory products such as SSDs and ram modules. We joined a few other press teams from other global publications for the tour and set about getting into the lovely air conditioned building, away from the humid air of Taiwan.

We were greeted at the front desk by a few of the engineers and higher ranking officials, where we signed in and were awarded our VIP passes before being led up to a conference room deeper within the building.

They’ve got a lot of great products to their name and the front hall was highlighted with a lit display, featuring all their latest awards and products.

Our gorgeous attire for the day, including some very swanky foot covers, take note that I’m being sarcastic.

Andy strutting his stuff.

Myself looking equally stunning in this white gown and blue foot cover combo.

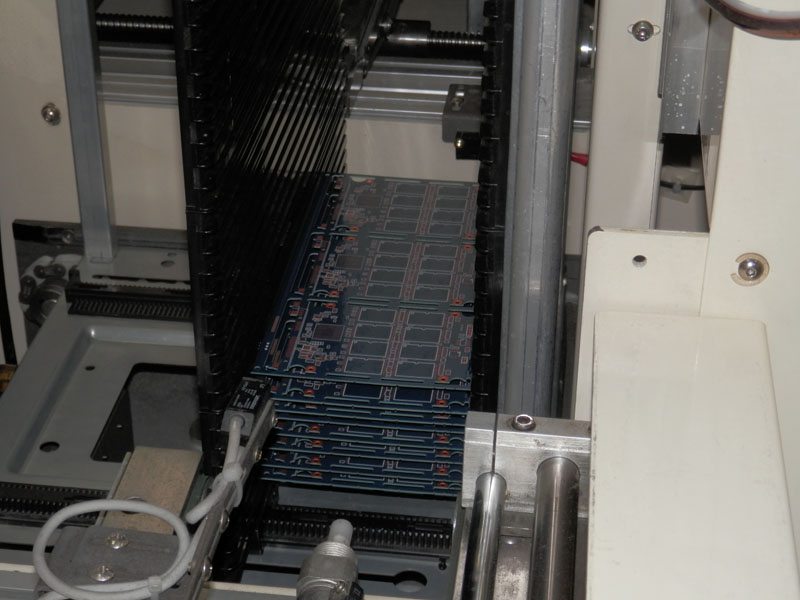

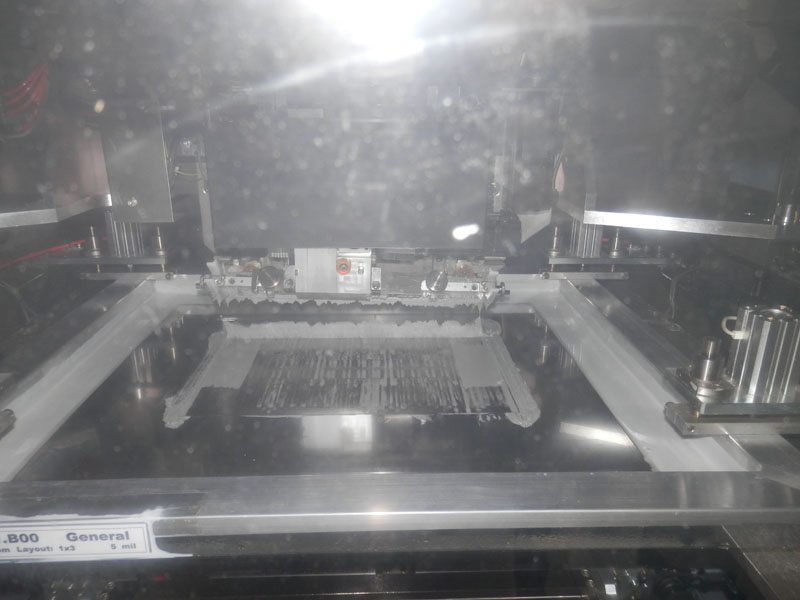

In this room, they solder memory modules onto SSDs, the products work their way down the automated production line one step at a time, although I was surprised at just how quick these machines can turn out a near finished product.

There are seemingly endless banks of these machines, each with a specific task such as cutting the PCB’s, soldering, checking, testing, heating and more.

Reels of components are rolled out like a ticker tape printer as each machine stamps the components onto the board and other machines solder them in place.

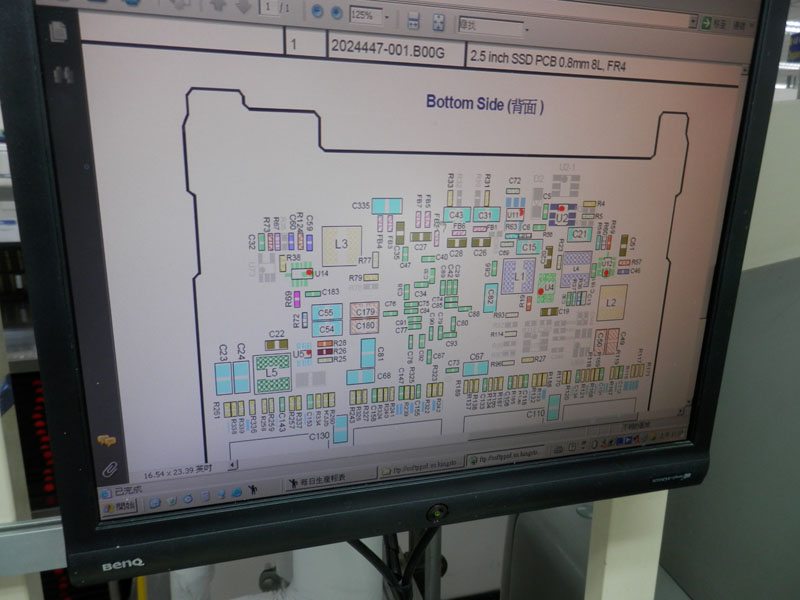

Each component is laid out on computer screen, which them assembles them based on the laid out specifications.

The boards are made in blocks, and then cut and drilled and labled, ready to be placed in their individual chassis.

This room is packed full of the components needed to create the modules, and given that there are a lot of tiny components to each SSD or memory module it’s no wonder they have so many shelves to store it all on (there were many more than you can see here).

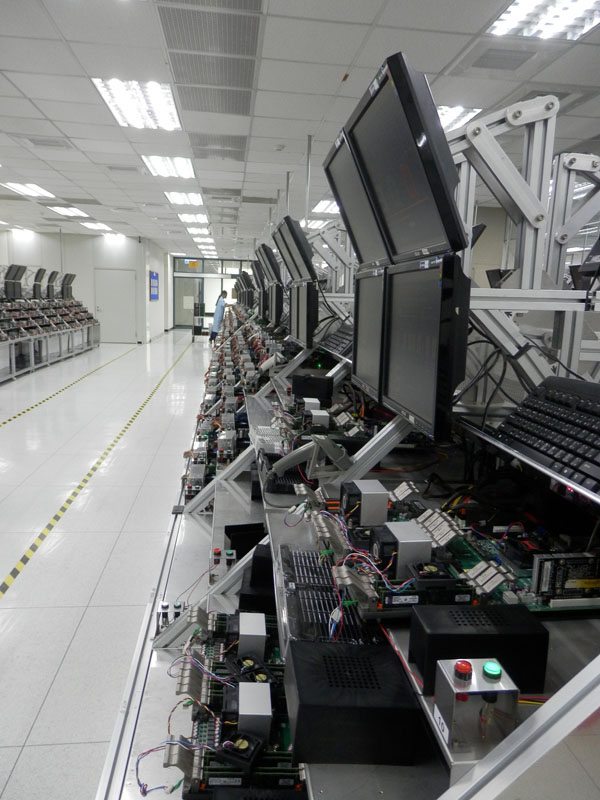

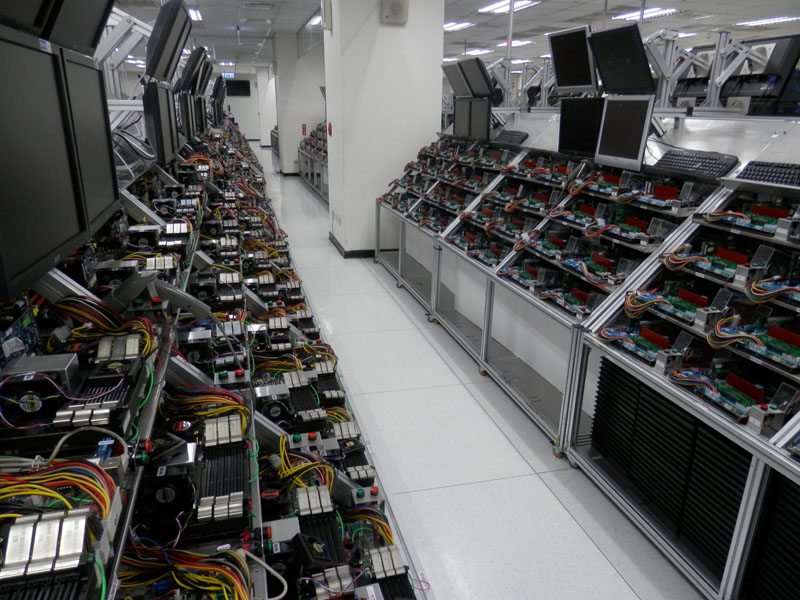

Testing is a big part of the manufacturing process, not to mention firmware testing, patching and similar tasks. Endless banks of test benches were setup for testing everything from SODIMMS, DDR modules and SSDs.

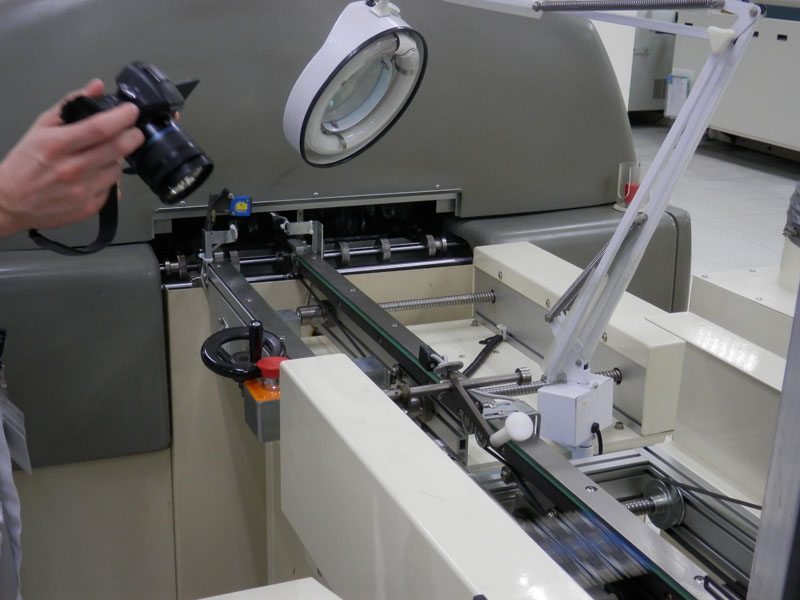

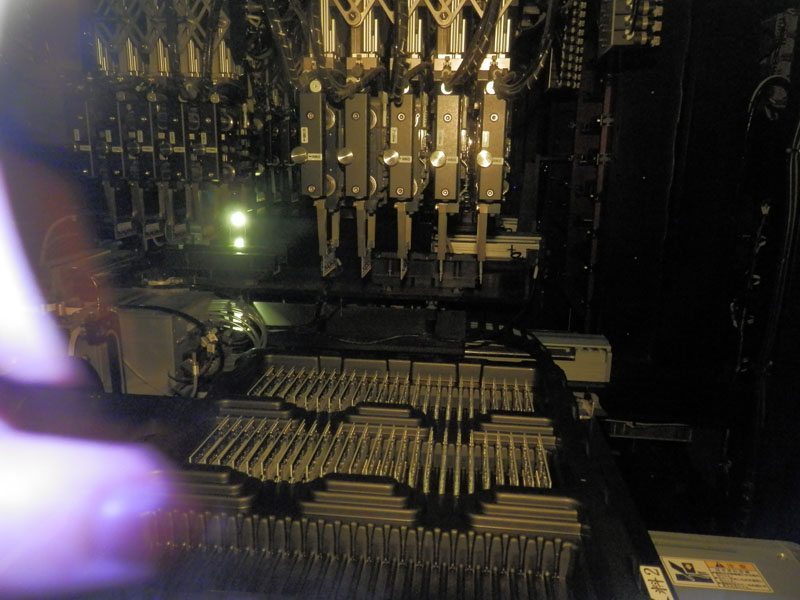

This machine is a high performance scanning machine, it takes photographs of the finished PCB and checks it against its database for errors, making sure every product is in perfect condition. This task used to be done by hand, but the high capacity demands of the factory means that this machine had to take over the task to speed up production.

It is capable of testing multiple boards at a time as you can see with the huge banks of PCBs lining the bottom of the machine.

Yet more testing equipment.

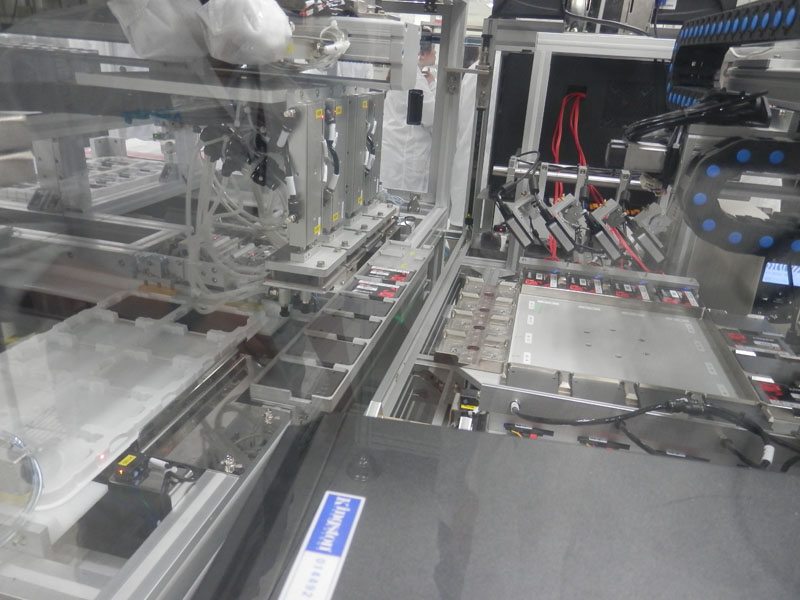

These complete machines apply the chassis to the products, as well as the first stages of printing and adding their labels.

Starting to look more like a retail product now.

The final finish can still be done by hand in some parts of the factory. These boards are now finished after their printing, soldering, cuttings, mounting, testing and labelling.

From here on, they are boxed, packed and shipped directly out to retailers. Everything prior to shipping is done in house by Kingston, as they don’t outsource any of the manufacturing.

It may not seem like much, especially given the clinical nature of the production line, but this is where Kingston SSD and memory products are born. The factory turns out tens of thousands of them and it’s rather hypnotising to see them churned out so efficiently on the production line.

Thank you Kingston for letting us tag along and see where the magic happens, as well as letting us share these images with the eTeknix community.