Laser Guns, Meatballs & 3D Printers – We Tour Alphacool HQ!

Peter Donnell / 8 years ago

Myself and the eTeknix boss Andy recently took a trip to Germany, and what better time to stop by and pay a visit to our good friends at Alphacool! The team there invited us to their newly upgraded offices and gave us the grand tour, showing us where the magic happens. It became clear very quickly why they’re such a popular brand and why their products are so loved around the world.

First up, they fed us, and we’re not going to pass up hospitality like that. From their nicely equipped kitchen, their staff take it in turns cooking for the office each day, and it came with a side of a beer or two too, pretty much the best way to start a meeting, wouldn’t you agree?

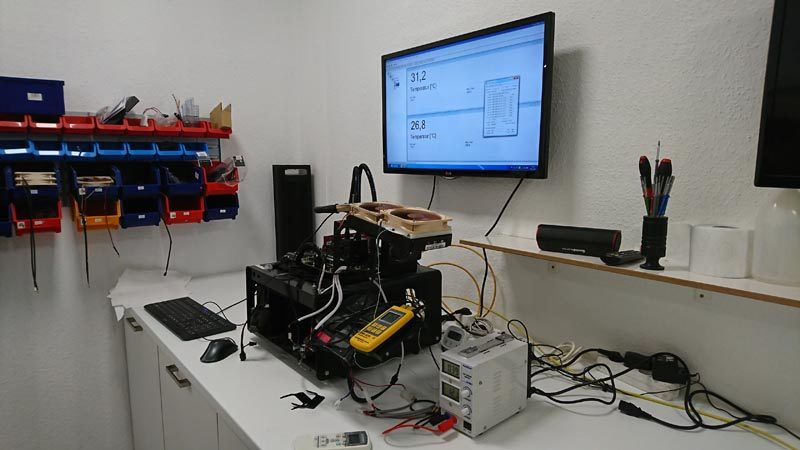

Right, so onto the hardware side. Here we see their main testing setup for everything from their prototypes to their finished products. Two modular test benches, ready to monitor any cooling hardware they require.

They fired up a quick demo, showing one of their pre-built AIO hybrids cooling an 8-core AMD CPU. Not getting into the technical performance just now thought, it was just a quick demo of things being powered on.

They design, prototype and finalise all their products on site. Here you’ll find them tinkering with drills, soldering irons and more to craft custom parts and tweak some of their 3D models by hand to help finalise the design.

In their back cupboards, you’ll find old, current and upcoming products that they’ve worked on too, which we’ll look at in a moment.

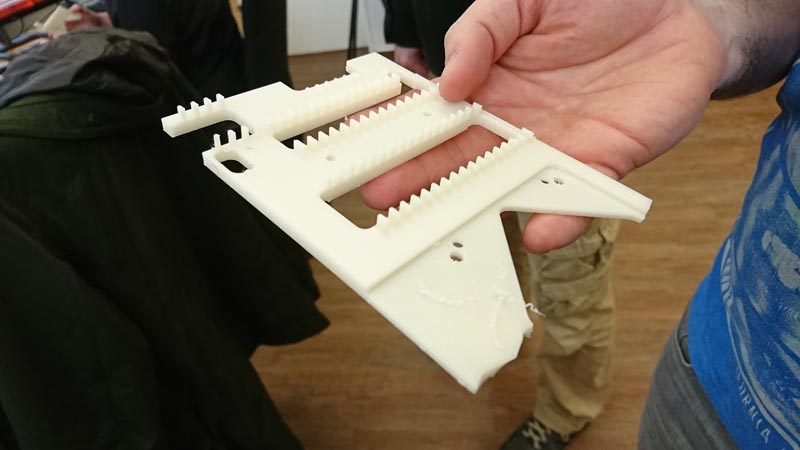

Here you can see one of their latest prototypes, a slick looking radiator, albeit one that still has some 3D printed components in the design phase.

It’s tailored towards modders, as the outer casing panels can be removed, allowing you to paint and tweak them easily.

This is what their CPU blocks look like before going to the factory for final production!

Some new reservoir designs sitting in the cupboard too, including one with a love Helix spiral.

Time for another break? Well, if they’re going to have this just sitting there it would be rude not to.

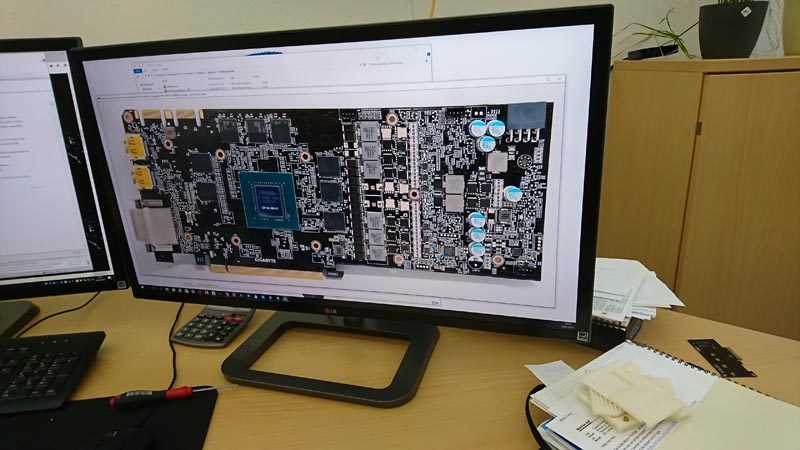

OK, back to work now. Here we see their scanning systems, and no we don’t know why they have those epic pink chassis, but we know you want one too. The one of the left is very interesting, it uses a tiny pin to 3D map hardware such as a GPU PCB. This process can take 5 days to complete but works better than lasers which would be thrown off by shiny materials on the cards surface.

When they’re not scanning, they’ll be 3D printing as well. They’ve got three models on tap here, with the middle one alone clocking in at around $40,000!

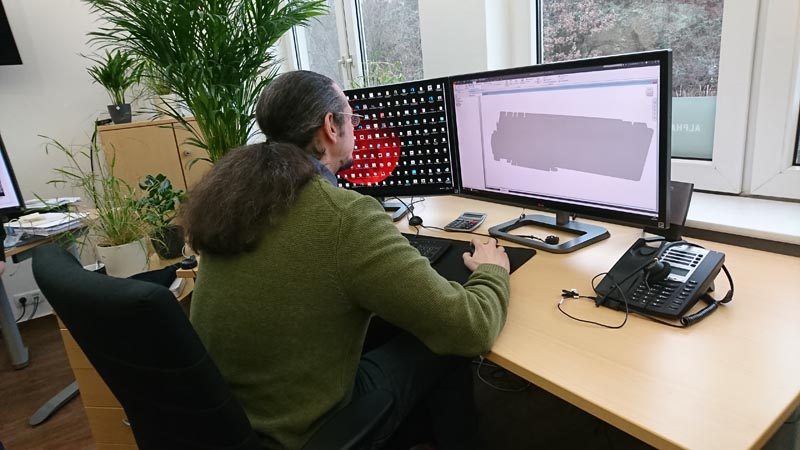

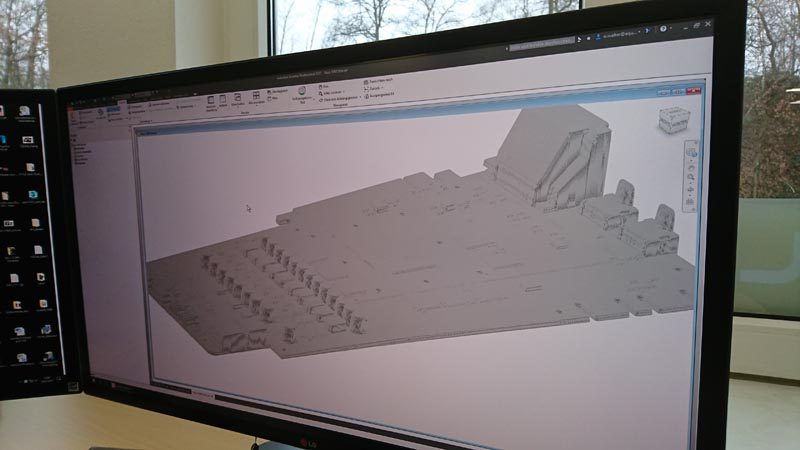

Back in the design rooms, we can see their temp doing the final tooling on a GPU block.

Looks pretty cool, right?!

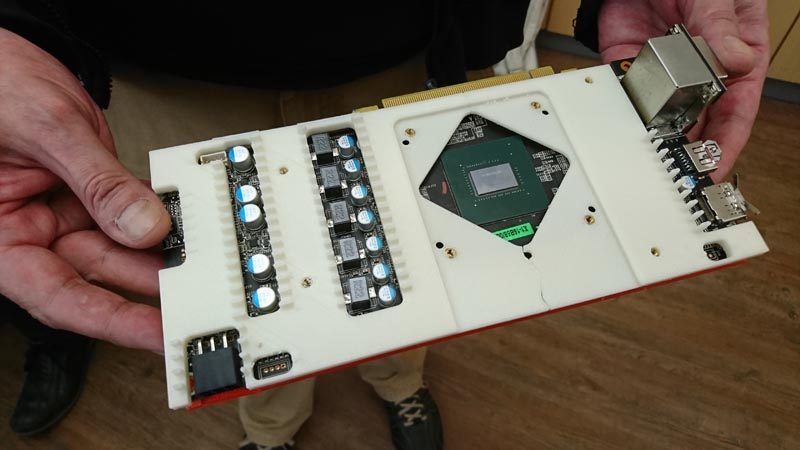

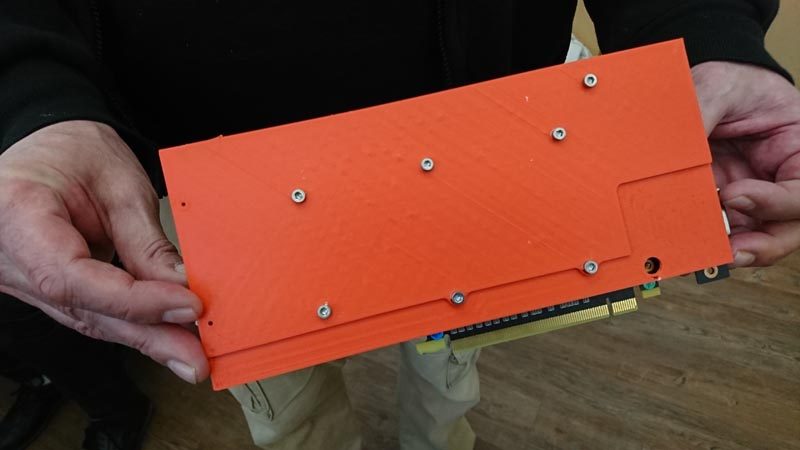

The 3D model team break up the components and design, tweaking them for compatibility, as all the parts have to be cut out by hand from the models.

The finished prototype can then be tested on the actual GPU PCB to ensure compatibility, before being tested in their lab. When they’re fully satisfied with the design, quality and performance, it goes off to the factory for mass production. However, even with all the technology here, it can still take a few months to get from start to finish on this process.

That you Alphacool for the tour, and we look forward to bringing our readers here at eTeknix a lot more coverage of their new products in the future.

As a closing note, the Alphacool team really know how to show their guests a good time, and took us for a few hours of laser quest! Thank you Alphacool, it was an awesome day out.