STEC’s CellCare Technology Improves Endurance of MLA Flash Memory by 13 Times

Peter Donnell / 13 years ago

STEC is a leading maker of solid-state drives, who said on Wednesday that the company has validated its proprietary CellCare technology’s ability to extend the endurance of 24nm consumer-grade multi-level cell (MLC) NAND flash memory to 40 000 program/erase cycles, which is greater than 13 times the manufacturer’s specified endurance metric of 3000 program/erase cycles.

CellCare Technology is a proprietary combination of hardware and firmware working together to improve MLC flash performance and endurance throughout the life of the solid-state drive. Key endurance-extending features of this patented technology include, flash parameter tracking per die, which delivers reduced and controlled wear; flash management through the lifetime, which delivers reduced wear, controlled performance, improved performance, and lower write/read latency; and advanced error correction with digital signal processing to improve data reliability and require a minimum of re-reads.

“This announcement opens up a lot of new opportunities, as cost is king in NAND and SSDs. Being able to take consumer-grade MLC NAND from 3000 cycles to 40000 cycles presents a huge leap in cost-effective enterprise endurance – enabling much more adoption,” said Alan Niebel, founder and chief executive officer for Web-Feet Research.

The new CellCare technology enables development of a new generation of STEC’s enterprise-class SSDs that utilizes low-cost cMLC NAND chips, while still achieving 10 full capacity random writes to the drive each day for five years, and data retention for three months (at 40°C) with no degradation in performance. This equates to approximately 7.3PB of data being written to a 400GB SSD over the life of the drive.

After applying STEC’s CellCare Technology in combination with its fourth-generation ASIC-based SSD controller, STEC engineers performed a series of JEDEC-standard tests, including a program/erase endurance and data retention stress test; a stress-test-driven qualification of integrated circuits; and a SSD requirements and endurance test.

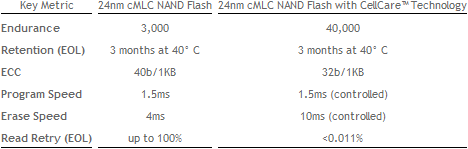

Results of the endurance testing are outlined in the table below:

“The results of the 24nm MLC endurance testing, performed at our San Diego R&D center, are testimony that the solid flash management algorithms and digital signal processing/error correction code within our patented CellCare technology bring true enterprise-class capabilities to consumer-grade flash memory. We have now tested the use of lower-cost 24nm MLC NAND with our CellCare technology to withstand the rigorous workload environments of enterprise storage applications – specifically, to provide for 40 000 program/erase cycles,” said Pablo Ziperovich, STEC’s vice president of flash channel development.

CellCare Technology is embedded in STEC’s full line of MLC NAND-based enterprise-class solid-state solutions, including its PCIe solid-state accelerators, ZeusIOPS SAS SSDs, and MACH16 SATA SSDs. STEC’s 24nm MLC NAND flash-based SSDs are currently in development and testing, with production anticipated for later this year.

Source: XBitLabs